Cabinplant International is world leading within turnkey process equipment for the food industry and focus areas on fish, shellfish, vegetables, berries and convenience foods.

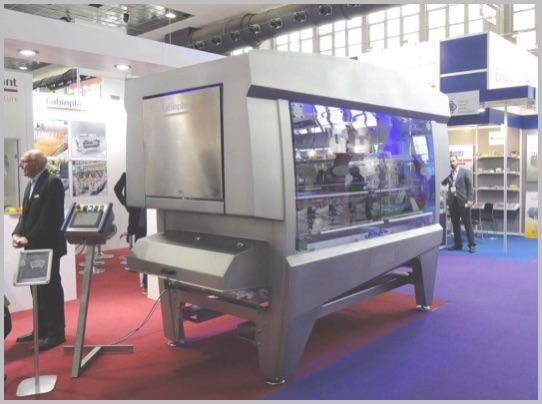

At the Seafood Procesing Global fair in Brussels, Belgium, the company presented their 2nd generation MULTI BATCHER with a new design and improved weighing software that significantly reduces the give-away compared to any other conventional weighing machines on the market. The principle of combinatorial weighing known from Cabinplant’s successful multihead weighing machines results in higher accuracy. The multi batcher is ideal for the handling of bigger batches (mackerel, herring, chicken, pork and beef) of up to 10 kg or more.

Once again Brahe design assisted Cabinplant in designing this MULTI BATCHER leaving an appearance of the machine that reflects the quality of the function and product itself.

Brahe design has supported Cabinplant for over a decade with industrial design during development of machinery such as this Multi Batcher and the Robot Trimming and Packing Line.

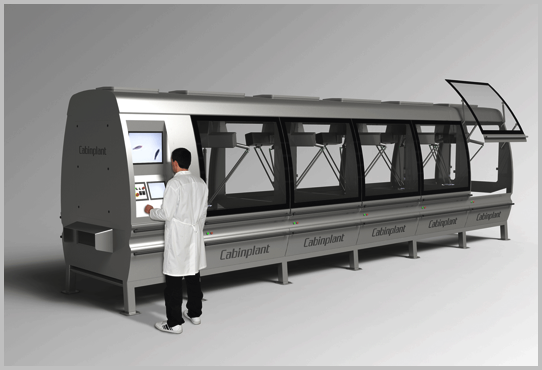

This ROBOT TRIMMING AND PACKING LINE is designed by Brahe design

After the internal functional test came out successfully, Brahe design did the ideation for a self supporting cabinet, final design proposal, ending up with a short videoanimation og the machine.

All of the processing steps are performed in the pick-and-place operation during which a robot transfers individual products from a feeding conveyor into the package.

The robot trimming and packing line was awarded the danish Product Prize 2011

Food Processing Equipment

Other companies and products:

Cabinplant

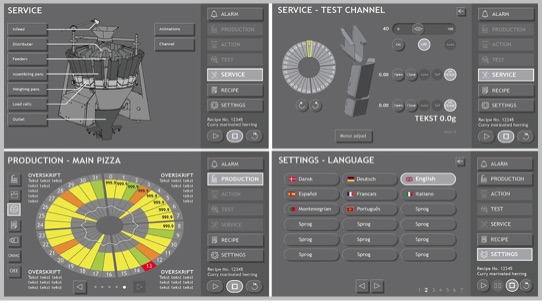

When upgrading their multihead weighing machine Brahe design supported the software engineers with a complete design of the HMI